The Ultimate Guide to Fillet Weld Quality Control: Ensuring Toughness and Longevity in Your Welded Joints

In the world of welding, guaranteeing the toughness and toughness of fillet welds is extremely important for the stability of bonded joints. The quality assurance measures applied during the welding procedure can considerably influence the structural soundness of the end product. From the selection of proper materials to the thorough evaluation of welds, each action plays an important role in figuring out the overall high quality of the weld joint. As we get started on this exploration of fillet weld quality assurance, we will certainly uncover essential aspects that influence weld strength, delve right into reliable assessment techniques, and review methods for protecting against common weld issues. Remain tuned to find just how grasping these techniques can boost the longevity and dependability of your bonded joints.

Value of Fillet Weld Top Quality Control

Making sure proper fillet weld quality assurance is critical in ensuring the structural integrity and long life of bonded parts in various industries. Fillet welds are commonly made use of in architectural steelwork, bridges, pressure vessels, pipes, and various other crucial infrastructure where the strength of the weld is crucial to total safety and performance. Quality assurance procedures such as aesthetic inspections, non-destructive testing, and adherence to welding treatments help identify prospective issues like absence of fusion, incomplete infiltration, undercutting, or too much reinforcement.

Trick Elements Impacting Weld Strength

Accomplishing ideal weld stamina requires mindful consideration of various vital elements that affect the honesty and resilience of the welded joint. The initial crucial variable is correct joint preparation, which includes cleansing the base metals to get rid of any type of contaminants that could weaken the weld. Additionally, the fit-up of the joint is necessary to guarantee appropriate penetration and blend of the filler product.

The option of the suitable welding strategy and specifications likewise plays a considerable function in establishing weld toughness. Variables such as heat input, travel rate, and electrode angle can affect the quality of the weld. Maintaining the right interpass temperature during multi-pass welding is essential to protect against breaking and make certain a strong bond in between the layers.

In addition, the choice of filler product and its compatibility with the base metals is important for attaining high weld strength. Making use of filler product with the appropriate mechanical residential properties can enhance the general honesty of the weld. Post-weld warmth treatment and correct assessment techniques are essential steps in guaranteeing the toughness and durability of the bonded joint.

Assessment Techniques for Weld Integrity

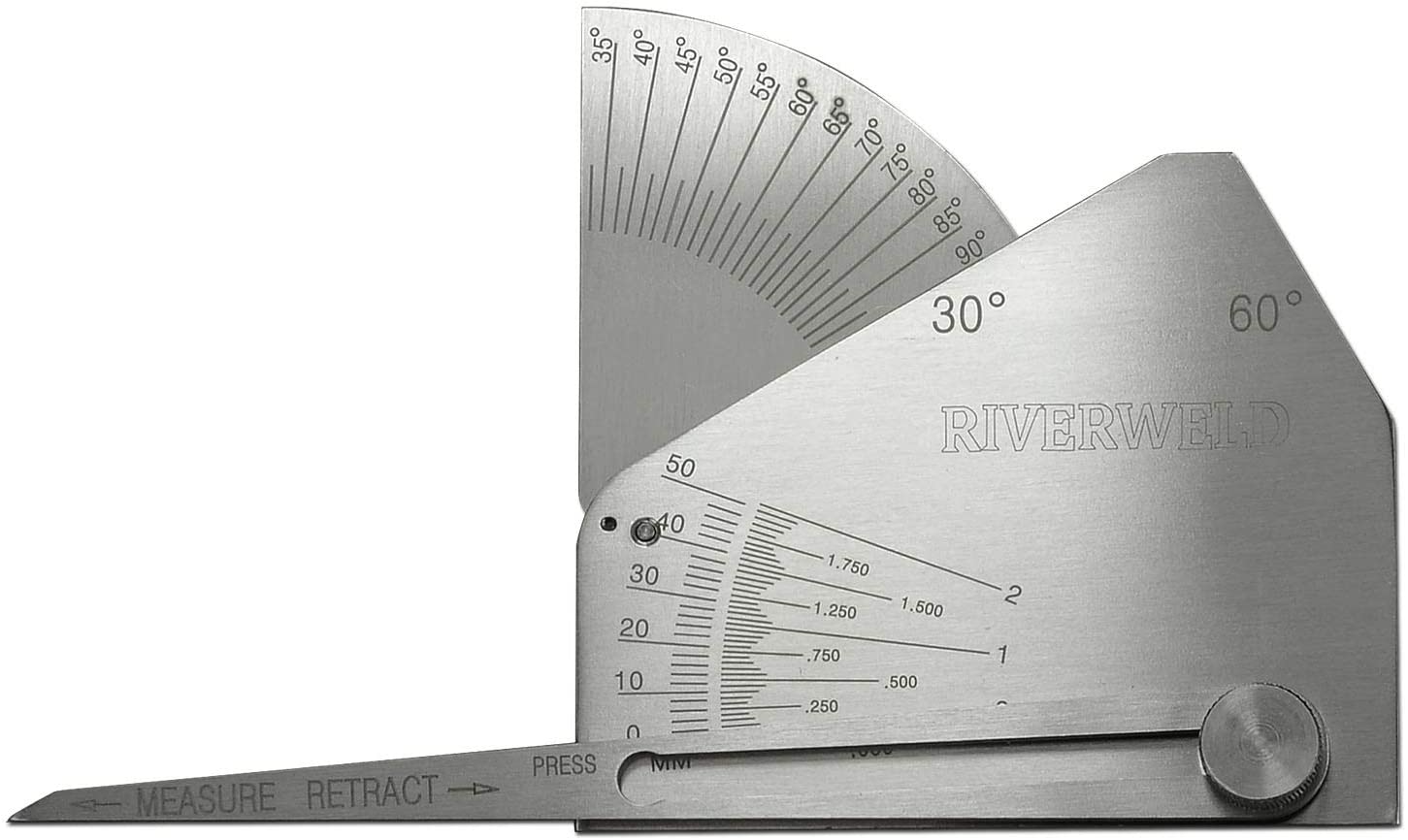

An additional vital examination approach is liquid penetrant testing, where a liquid color is used to the weld surface area - Gauge Fillet Weld. The color seeps into any type of surface-breaking problems, making them visible under UV light. This approach works for detecting problems that might not be visible to the nude eye

Ultrasonic screening is likewise commonly used for examining weld integrity. High-frequency sound waves are directed into the weld, and any kind of interruptions in the audio wave pattern indicate possible defects like fractures or absence of fusion.

These inspection methods play a crucial function in making certain the quality and reliability of welds, eventually adding to the total strength and sturdiness of click here for more bonded joints in commercial setups.

Stopping Usual Weld Issues

In order to maintain the architectural honesty of welded joints in commercial applications, it is essential to apply safety nets to address typical weld issues. One common issue is absence of combination, where the filler material stops working to bond adequately with the base metals, bring about vulnerable points in the weld. This can be protected against by making sure correct warm control and using the correct welding strategy.

Another constant issue is porosity, brought on by gas entrapment in the weld metal throughout the welding process. To stop this, it is important to clean up the base steels completely, make use of completely dry electrodes, and preserve an ideal welding setting with appropriate air flow.

Furthermore, splits in welds can jeopardize the joint's stamina. To prevent this issue, it is essential to manage the cooling rate after welding, use pre-heating when essential, and select appropriate welding parameters.

Enhancing Bonded Resilience With Appropriate Techniques

One essential technique to improve weld durability is to ensure correct weld bead placement. By placing the weld bead precisely within the joint, the weld's toughness and resistance to tiredness can be substantially enhanced.

Picking look at here now the appropriate filler metal and guaranteeing the tidiness of the base metals can stop additions and various other problems that can compromise the weld's durability. By executing these correct methods, welders can make sure that their welded joints display outstanding toughness and durability, fulfilling the highest top quality criteria.

Conclusion

To conclude, maintaining excellent quality control requirements for fillet welds is essential for making certain the stamina and longevity of bonded joints. By comprehending the essential variables impacting weld stamina, using examination techniques for weld stability, stopping common weld defects, and employing proper techniques, welders can improve the Our site total toughness of their welds. It is imperative to focus on quality assurance procedures to generate reputable and long-lasting bonded joints.

In the realm of welding, guaranteeing the strength and toughness of fillet welds is critical for the stability of welded joints. As we get started on this expedition of fillet weld quality control, we will certainly discover necessary aspects that affect weld strength, delve right into efficient examination methods, and discuss methods for preventing common weld problems.Accomplishing ideal weld strength calls for cautious factor to consider of different key elements that influence the integrity and toughness of the bonded joint (Gauge Fillet Weld).In conclusion, keeping high top quality control requirements for fillet welds is critical for making sure the strength and longevity of welded joints. By understanding the vital aspects influencing weld stamina, making use of examination approaches for weld honesty, avoiding common weld flaws, and employing proper strategies, welders can enhance the general resilience of their welds